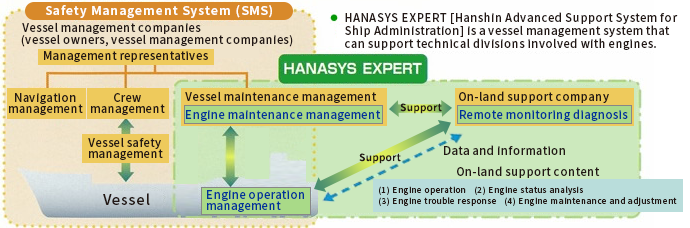

HANASYS EXPERT

HANASYS EXPERTHanshin Advanced Support System for Ship Administration

HANASYS-EXPERT is a system that can remotely monitor the status of a vessel’s main engine through communication between the vessel and land. It can detect predictive signs of malfunctions or failure, and take appropriate measures before they develop into serious conditions. EXPERT's diagnosis can confirm and identify changes in the status of the main engine through comparisons with factory operation results and trends of various measurement values. This has the benefits of allowing locations of age-related deterioration to be estimated, and quantitative judgments to be made on the time periods for carrying out maintenance management. In addition to data such as temperature and pressure that can be acquired by conventional monitoring equipment, high-performance sensors such as cylinder combustion pressure sensors, inter-ring pressure sensors, fuel injection pipe combustion pressure sensors, and crankshaft angle detection sensors can allow the status to be monitored in greater detail.

The Hanshin Advanced Support System for Ship Administration was built based on this technology, and certified in 2010 as advanced support system for ship administration by the Ministry of Land, Infrastructure, Transport, and Tourism on an actual vessel for the first time in the domestic shipping industry.

Subsequently, plans were made to implement the Advanced Support System for Ship Administration, and installation has actually been completed on 21 vessels.

Aiming to achieve efficient operation of domestic coastal vessels

- Monitoring and diagnosing engines from land, using high-performance sensor combustion analysis technology and IT technology

- Optimizing maintenance management for propulsion engines

- Ensuring safety and economic effectiveness

Anticipated effects of introduction

-

- Serious failures can be prevented in advance

- Improvement of safety, reliability, and efficiency in navigation

-

- On-land support for navigation and maintenance management work

- Reduction of work in vessels

-

- Reduction of maintenance expenses made possible by engine diagnosis and part status monitoring

- Optimization of part replacement for inspection and maintenance

Monitoring sensors

High-performance sensors

- Cylinder combustion pressure sensors

- Inter-ring pressure sensors

- FO injection pipe combustion pressure sensors

- Cylinder liner temperature sensors

- FO pump plunger temperature sensors

- Intake air temperature sensors

- Crankshaft angle detectors

General sensors

- Lubricating oil temperature and pressure

- Fuel oil temperature and pressure

- Cooling water temperature and pressure

- Revolution speed, fuel rack scale, etc.

Manual input

Navigation information

- Wind direction, wind speed

- Weather, waves

- Loading status

- Atmospheric pressure, humidity

- Sensory information

- Wear measurement values

- Properties of fuel oil and lubricating oil

Inquiries About Products

Please feel free to inquire with us on our products, services, or any other matters.