- HOME

- Products & Services

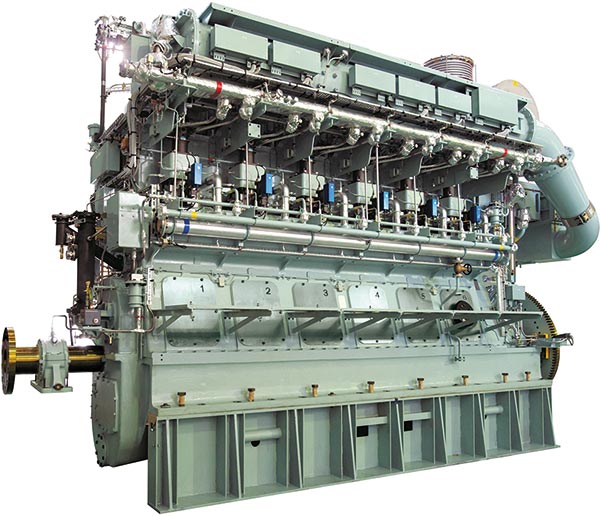

- Low Speed 4-stroke Diesel Engine

- Electronically Controlled Engine

Electronically Controlled Engine

This model is based on the LA and LH-L model engines with the fuel injection mechanism converted to electronic control. In place of a cam, the fuel injection pump is operated hydraulically, and controlling the hydraulic oil pressure makes it possible to change the fuel injection timing or fuel injection pressure profiles as desired. Therefore, each force component can be tuned separately to improve the fuel oil consumption in part-load areas.

Advantages

The advantages of the Hanshin electronically controlled engine are that it is based on the proven low speed 4-stroke diesel engine, with only the fuel injection changed to electronic control.

Everything aside from the electronically controlled components has the same structure as conventional models, so it has the same reliability and durability.

Structure

In the electronically controlled engine, the combustion pump is driven by hydraulic oil pressure in place of a cam to carry out fuel injection.

Therefore, fuel injection is not related to the load or revolution speed of the engine, so it is possible to make independent settings for fuel injection patterns and timing for each part-load area. This allows optimal settings to be designated at all load areas.

Fuel oil consumption comparison with conventional model

Operation mode settings

Furthermore, the electronically controlled engine can accommodate multiple operation mode settings.

In the example shown in the figure to the left, the operation modes for navigation and cargo loading have been set. By optimizing each mode, improvements in performance during cargo loading, which had to be sacrificed with conventional models, can be expected.

Development background

Environmental initiatives for marine engines include the reduction of NOx and CO2, but combining measures to address both of these issues is an extremely difficult challenge for engine manufacturers. At the Company, we thought that the use of an electronically controlled system would be an effective and essential means of responding to both issues. Furthermore, we focused on the fact that an electronically controlled system for marine low speed 4-stroke diesel engines had not yet been developed, and took a global lead to realize such a system using domestically-produced technology.

Reasons for selection by customers

This engine can achieve low fuel oil consumption at all load areas (particularly medium and low loads), and can accommodate settings for multiple operation modes (propulsion, cargo loading) in accordance with its usage conditions. It also has highly improved performance, making it an engine that has earned the trust of customers.

Furthermore, it is a reliable product that has a higher level of consideration for environment-friendliness among all of our previous engine product series.

Difficulties during development

Some difficulties encountered included thermal countermeasures for the hydraulic control valve, and steps to prevent sensor damage caused by problems with the drain discharge. We also struggled with measures to respond to high hydraulic pressure, such as double wall pipe systems in vessels and measures for vibration caused by hydraulic oil pressure.

What types of vessels are the engines suitable for?

They are suitable for vessels engaging in low-load operation and vessels using engines for both navigation and cargo loading.

Introduction video of low speed 4-stroke electronically controlled engine

Particulars

Low speed 4-stroke LA series engine

| Model | Number of cylinders | Output (kW) | Speed (min-1) | Cylinder bore (mm) | Stroke (mm) |

|---|---|---|---|---|---|

| LA32E | 6 | 1,618 | 280 | 320 | 680 |

Low speed 4-stroke LHL series engine

| Model | Number of cylinders | Output (kW) | Speed (min-1) | Cylinder bore (mm) | Stroke (mm) |

|---|---|---|---|---|---|

| LH41LAE | 6 | 2,647 | 240 | 410 | 800 |

| LH46LAE | 6 | 3,309 | 220 | 460 | 880 |

- The LHL series engine can also be equipped with a reversing gearbox.

Inquiries About Products

Please feel free to inquire with us on our products, services, or any other matters.