- HOME

- Products & Services

- Low Speed 4-stroke Diesel Engine

- Gas Engines

Gas Engines

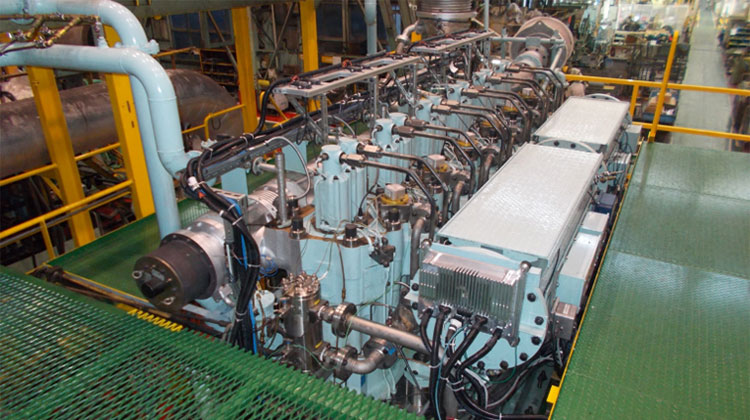

Utilizing the same basic structure as the existing low speed 4-stroke diesel engine, which has earned a high level of trust from customers, but with the combustion chamber section converted to a gas engine, this is the world's first gas engine developed as a low speed 4 stroke engine. In terms of environmental performance, it fulfills the Tier III NOx regulation from the International Maritime Organization (IMO), and does not generate soot (PM) or sulfur oxide (SOx). Additionally, it is an environment-friendly engine with a thermal efficiency ensured to be higher than that of existing diesel engines.

Advantages

It is based on the proven low speed 4-stroke diesel engine, with only the combustion chamber section converted to a gas engine.

Everything aside from the combustion chamber section has the same structure as conventional engines, so it has the same reliability and durability.

It employs an electric ignition system as a gas mono-fuel combustion engine, and is capable of operating only on gas from startup to high loads.

Structure

The gas engine was created with consideration for a simplified structure, where an air-fuel mixture is taken into the cylinder and an electrical ignition system is used to ignite the mixture with a spark plug.

Two spark plugs are provided in each cylinder, so that operation can be continued even in the event that ignition failure occurs with one of them.

Control system

In gas engines, various types of control are carried out in order to ensure stable combustion.

In existing diesel engines, only the fuel injection volumes are controlled in accordance with the engine load. In gas engines, however, intake air volumes are also controlled according to the engine load in addition to the fuel injection volumes.

Therefore, two types of valves are installed to adjust the intake air volume - one to bypass the exhaust, and another to bypass the intake air.

Furthermore, under extremely low loads an intake air throttling valve is also provided to adjust the intake air volume in addition to the bypass valves.

Basically, control of the fuel injection volume is carried out by adjusting the gas injection period, but if the gas volume is changed significantly the gas pressure is also controlled.

While gas engines are in operation, the ignition timing is controlled so that the maximum cylinder combustion pressure can be maintained properly at all times. Therefore, pressure gauges are installed in all cylinders to constantly analyze the cylinder pressure while controlling the ignition timing.

Gas supply system

Comparison of efficiency with conventional model

In the left figure, NOx is shown on the horizontal axis and thermal efficiency on the vertical axis. The fuel oil consumption decreases the higher the thermal efficiency.

For the G30(A), the Tier III NOx regulation mode is shown, and for the G30(B) the Tier II NOx regulation mode is shown. In the G30(A) mode, the Tier III NOx regulation is fulfilled while achieving a higher thermal efficiency than the existing LA32 model diesel engine.

Since the Tier III NOx regulation is not applied in the coastal areas of Japan, compliance with the Tier II NOx regulation is sufficient, and under the G30(B) mode even higher thermal efficiency can be achieved.

Development background

The benefits of using gas as a fuel are that its reserves are more abundant than liquid fuel (petroleum), and that the price of gas will become lower than that of liquid fuel in the future. In addition, gas has excellent environment-friendliness. While liquid fuels require various types of technology to be applied to comply with regulations for sulfur oxide (SOx), nitrogen oxide (NOx), and soot (PM), gas engines can fulfill all of these regulations at once, which is the reason the decision was made for their development.

Difficulties during development

Development of the gas engine succeeded after a total of 6 years which consisted of 2 years for single-cylinder engines and 4 years for full-scale engines. During these 6 years, 8 personnel members consisting of 3 main supervisors and 5 support personnel were involved with it. Tests to optimize the flow of the air-fuel mixture in the fuel chamber were repeated for both single-cylinder engines and full-scale engines regardless of size, and tests to optimize the control during sudden load fluctuations were conducted numerous times during the 4 years of work on full-scale engines. These were very difficult parts of the process, but development was finally successful thanks to the cooperative efforts of many people.

Introduction video of low speed 4-stroke gas engine

Particulars

Low speed 4-stroke gas engine

| Model | Number of cylinders | Output (kW) | Speed (min-1) | Cylinder bore (mm) | Stroke (mm) |

|---|---|---|---|---|---|

| G30 | 6 | 1,422 | 290 | 300 | 720 |

Inquiries About Products

Please feel free to inquire with us on our products, services, or any other matters.